Polycrystalline corundum

Polycrystalline corundum

Polycrystalline corundum is based on black corundum, adding new elements in the production process, optimizing the main crystal image of black corundum, its color is brown-black, with high hardness, strong toughness, and good self-sharpness.

Polycrystalline corundum retains the advantages of black corundum with good self-sharpness, high sharpness, less heat generation, and high surface finish, which greatly improves the durability of black corundum.

1.2 Polycrystalline corundum indicator

Polycrystalline corundum is a new type of abrasive developed by the Yeda team for many years, and the particle size composition implements national standards and can also be customized according to customer needs

Chemical indicators

|

name

|

Particle size range |

Typical chemical composition |

|||

|

Al2O3(%) |

Fe2O3(%)

|

SiO2(%) |

TiO2(%)

|

||

| Polycrystalline corundum |

F10-220 |

62 |

10

|

16

|

3

|

Physical metrics

Color: brownish black

Hardness: Vickers hardness 2100 KG/mm2

Crystal: Tricrystalline square system

True Specific Gravity: 3.6g/cm3

Polycrystalline corundum advantages

2.1 Performance improvements

1. Good durability

Polycrystalline corundum is more than 30% more durable than the original black corundum

2. Good hydrophilicity

The particle surface of polycrystalline corundum has higher hydrophilicity than black corundum abrasive, and the binding strength of resin is stronger.

3. Good self-sharpness

The polycrystalline microstructure of polycrystalline corundum determines that it has good self-sharpness

4. Good heat dissipation

The polycrystalline microcrystalline grinding mechanism of polycrystalline corundum determines that it has good heat dissipation performance.

5. Good value for money

The price of polycrystalline corundum is lower than that of first-class brown corundum, but the performance is basically the same as that of first-class brown corundum, so it has a higher cost performance.

Polycrystalline corundum uses

3.1 Make resin abrasives

|

|

|

|

Manufacture of resin abrasives The use of polycrystalline corundum and other abrasives composite to make resin abrasives, can effectively improve the sharpness and durability of the abrasives. |

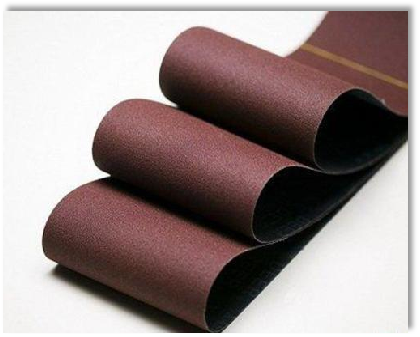

3.2 Manufacture of coated abrasives

|

Manufacture of coated abrasives Polycrystalline corundum or composite other abrasives are used to make abrasive cloths, sandpaper, sponge blocks, etc. |

|

|

|

|

|

3.3 Make fiber abrasives

|

Make fibers Use polycrystalline corundum or composite other abrasives to make nylon wheels, cleaning cloth, drawing wheels and other fiber abrasives |

|

|

|

|

|

Polycrystalline corundum quote

|

name |

specification |

wrap |

Ex-factory tax included Unit price (yuan / ton) |

|

Polycrystalline corundum |

F24-36 |

Neutral pouch/ton bag |

3500 |

|

F46-60 |

3600 |

||

|

F70-80 |

3500 |

||

|

F90-100 |

3600 |

Follow WeChat public account

More exciting waiting for you!

Tel:+86-371-63118666 / 400-071-5558

E-mail:vip@hnyeda.com

Add:Shengrun Industrial Park, Liuzhai Town, Xinmi City, Henan Province

Add:Zhangzhuang Industrial Park, Fushan County, Linfen City, Shanxi Province

Copyright © 2020 Henan Yeda New Material Technolohy Co., Ltd 豫ICP备2021001641号